Mr. zptouch01

Leave a message Mr. zptouch01

Mr. zptouch01

Mr. zptouch01

Leave a messageBasic concepts of PCBA analysis

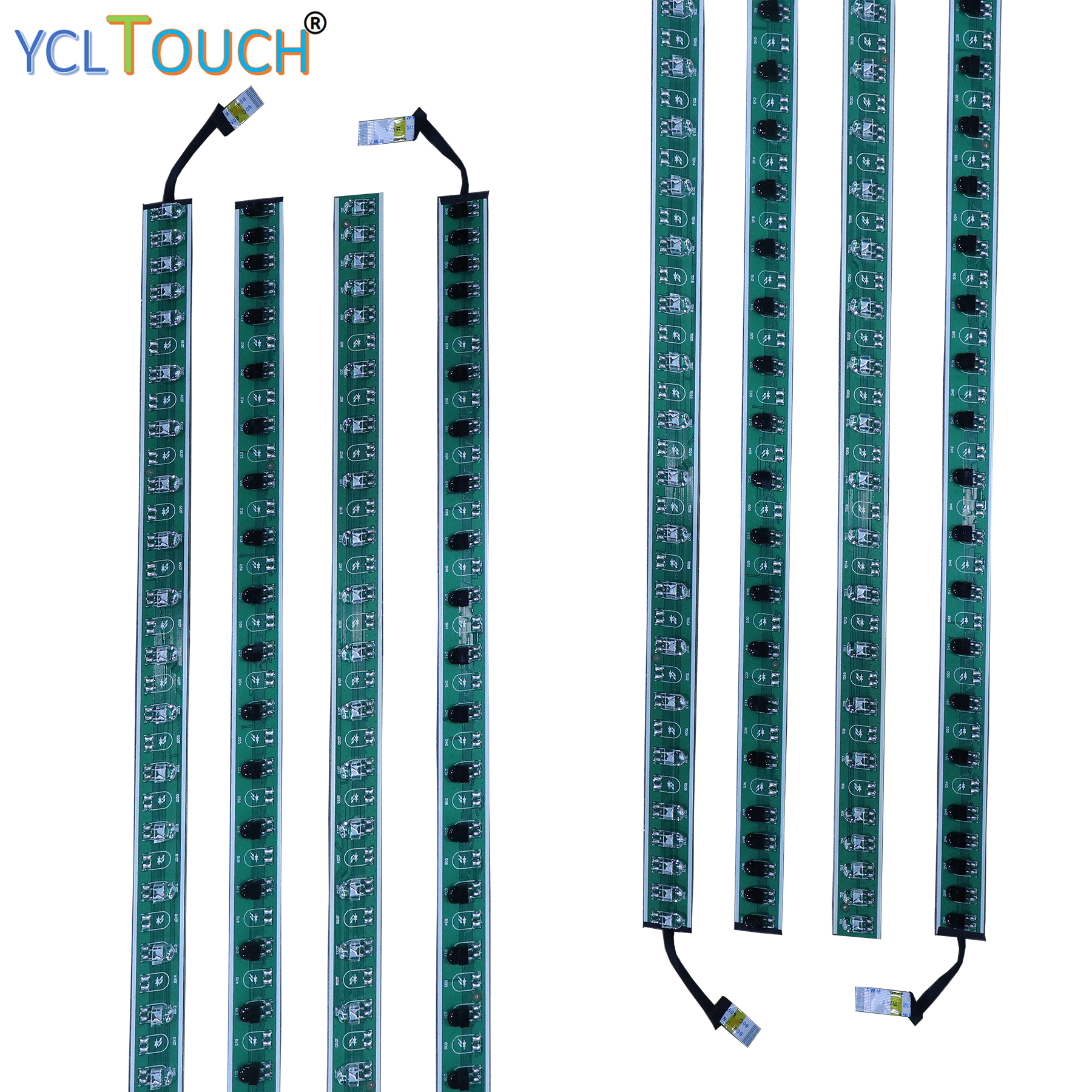

PCBA stands for Printed Circuit Board Assembly, which means printed circuit board assembly. PCBA analysis is the process of conducting a thorough, in-depth study of this component. In the field of electronic device manufacturing, PCBA is a product form in which electronic components are mounted on a printed circuit board and electrically connected. infrared PCBA analysis aims to ensure the quality, performance and reliability of PCBs by detecting, evaluating and optimizing them in multiple dimensions to ensure the stable operation of the entire electronic system. For example, in the production of smartphones, PCBA is the core component, and its quality directly affects the function and life of the mobile phone.

The main content of PCBA analysis

1. PCBA visual inspection

2.PCBA electrical performance test

3.PCBA functional testing

The importance of PCBA analysis

In today's increasingly competitive electronics manufacturing industry, the importance of PCBA analysis is becoming more and more prominent. On the one hand, high-quality PCBA analysis can effectively reduce the defective rate of products and reduce production costs. Because PCBA problems are discovered and solved in time during the production process, the high cost of troubleshooting and repair after the subsequent assembly is completed is avoided. On the other hand, a reliable PCBA analysis helps to boost a business's brand image. Consumers have higher and higher requirements for the quality of electronic products, and only products that have undergone strict PCBA analysis and guaranteed quality can win the trust and favor of consumers and enable enterprises to occupy a favorable position in the market competition. For example, a well-known mobile phone brand has been widely recognized for its product quality and steadily increased its market share by virtue of its high attention and strict implementation of PCBA analysis.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.