What is the difference between a chip and PCBA?

2024-11-26

Definition

- Chip is a kind of integrated circuit, which integrates a large number of microelectronic components (such as transistors, resistors, capacitors, etc.) on a small piece of semiconductor material (usually silicon). It is the core component of electronic products, mainly responsible for processing and storing electronic signals. Perform data operations and instructions execution.

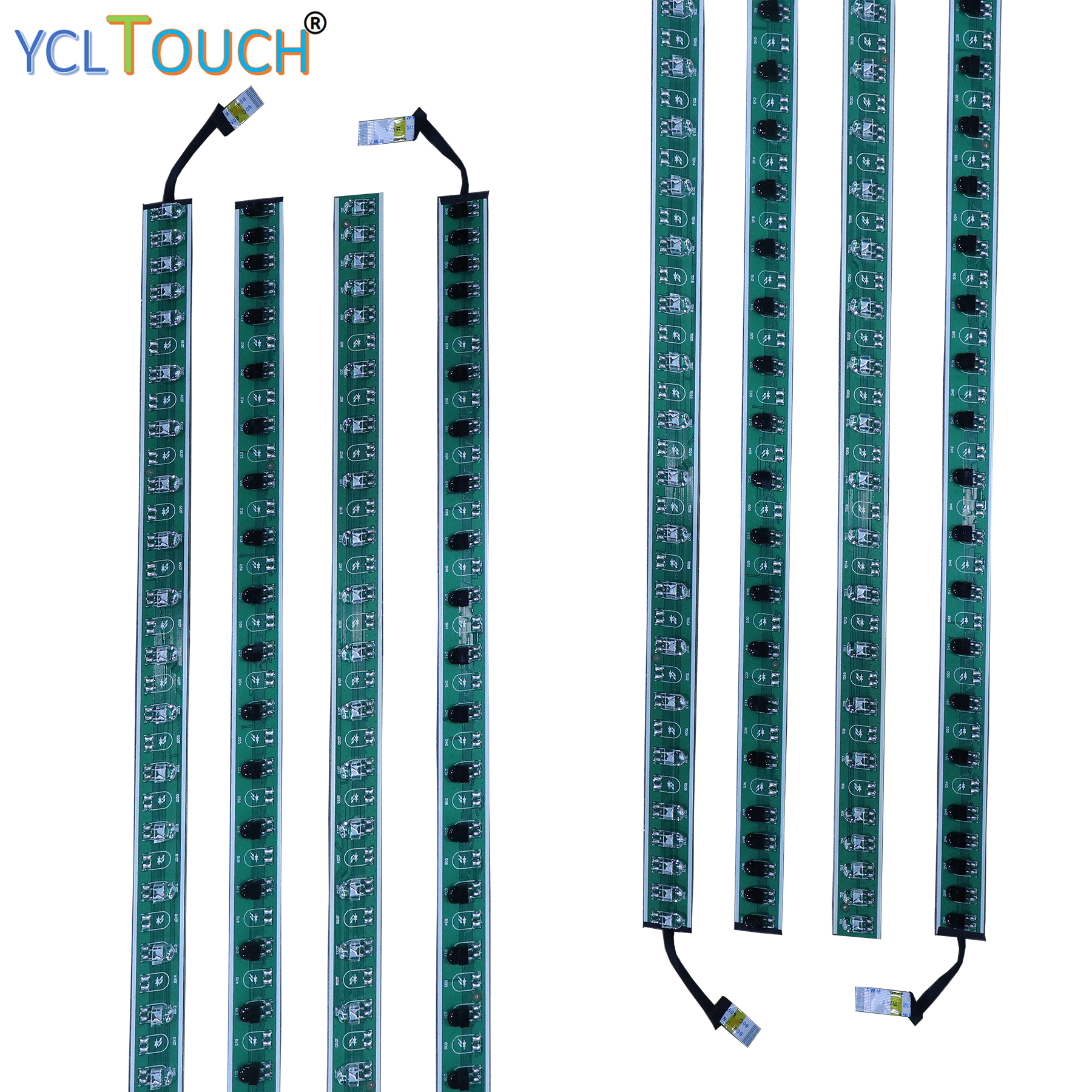

- Infrared PCBA (Printed Circuit Board Assembly) is a printed circuit board component, which is the product after a series of assembly processes. It includes a printed circuit board (PCB) and a variety of electronic components installed on it, such as chips, resistors, capacitors, inductors, etc., and the electrical connection is realized by means of welding. PCB can be regarded as a small electronic system platform with complete functions, which can realize specific electronic functions. For example, the motherboard of a mobile phone is a typical PCB.

Functional focus

- The functions of the chip mainly focus on the core operations such as data processing, storage and transmission. Consider the chips in smartphones, which process various kinds of data from sensors (like cameras, accelerometers, etc.) and run operating systems and various applications.

- The function of PCBA is realized based on the cooperation of various components contained in it. PCBA not only has chips to process data, but also includes other passive components for signal conditioning, power management and other functions. A PCBA can contain more than one chip, they cooperate with each other to make PCBA as a whole to achieve such as communication, control, display and other complex functions, for example, on the computer motherboard PCBA, CPU chip, graphics chip and other chips together to ensure the normal operation of the computer.

Physical structure

- The chip is usually an independent, small package, which has a variety of physical shapes, such as square flat package (QFP), ball grid array package (BGA), etc. The chip is mainly made of semiconductor wafer through cutting, packaging and other processes. It is relatively small in size, and its pins or contacts are mainly used to connect with external PCBA to transmit signals and power.

- PCBA is a multi-layer circuit board structure with various wires and pads for mounting components. PCBA is much larger than the chip area, it has a dedicated area for the chip and other components, and through the internal copper wire to achieve the electrical connection between the individual components. In the production process of PCBA, the printed circuit board is first made, and then the chip and other components are installed to the specified location, and the PCBA is formed by welding and other processes.

Manufacturing technique

- Chip manufacturing is a highly complex and precise process that involves high-end technologies in many fields such as semiconductor physics and chemistry. It mainly includes wafer fabrication (such as lithography, etching and other processes), chip packaging (such as plastic packaging, ceramic packaging, etc.) and other steps to ensure the realization of the circuit structure and function inside the chip.

- The PCBA manufacturing process includes the fabrication of printed circuit boards (PCBS) and the assembly of components. PCB fabrication needs to go through processes such as design layout, etching circuit, drilling and so on. Then various components (including chips) are installed on the PCB through surface mount technology (SMT) or plug-in technology, and finally the manufacture of PCBA is completed through welding and testing. In PCBA manufacturing, chip installation is one of the key steps, and the accuracy and quality of chip installation directly affect the performance of PCBA.

Application scenarios

- Chips are mainly supplied to electronics manufacturers as core components for integration into PCbas of various electronic devices. For example, the communication chip produced by the chip manufacturer will be purchased by the mobile phone manufacturer for the manufacture of the mobile phone PCBA, so as to realize the communication function of the mobile phone.

- PCBA is widely used in all kinds of complete electronic equipment, and is the key part to realize the function of the equipment. From consumer electronic products (such as smart phones, tablets) to industrial control devices (such as PLC controllers), and then to automotive electronics (such as the central control board PCBA of automobiles), PCBA is the place where PCBA plays its function, and different PCBA will integrate different types and numbers of chips according to the requirements of their application scenarios.

Mr. zptouch01

Mr. zptouch01