Mr. zptouch01

Leave a message Mr. zptouch01

Mr. zptouch01

Mr. zptouch01

Leave a messageDefine the difference

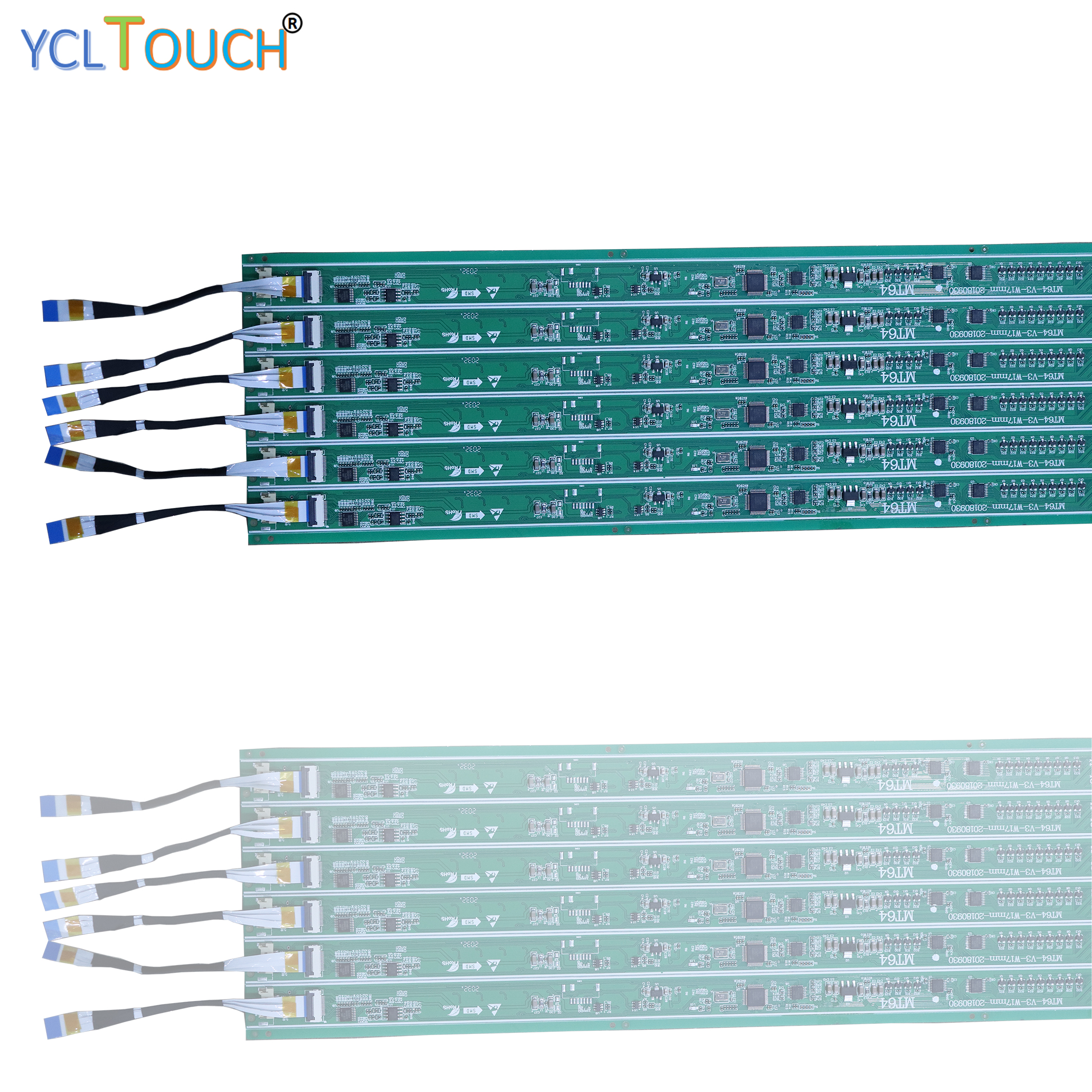

PWB (Printed Wiring Board) is a printed wiring board, mainly through physical or chemical methods, forming a conductive circuit pattern on the surface of the insulating material, it is a basic circuit board, focusing on the layout and connection of the line, usually does not contain electronic components. It's like a house frame without furniture, just with a built-up of the route.

Infrared PCBA (Printed Circuit Board Assembly) is a printed circuit board assembly, which is based on PWB, various electronic components (such as chips, resistors, capacitors, etc.) are assembled to the printed circuit board through soldering, plug-ins, etc. A PCB can be thought of as a house that has been renovated and furnished, and is a complete component that can realize the function of a specific circuit.

Differences in feature implementation

The PWB itself only provides the physical basis for the circuit connection. For example, on the PWB of a simple LED light circuit, it only has the line to let the current pass through, but it cannot directly realize the function of making the LED emit light.

Because the PCB is equipped with components, it can realize the complete circuit function. For the LED lamp example just now, after installing the LED lamp beads, current limiting resistors, and the wires connecting them on the PCBA, the LED can be driven by the power supply to make the LED shine and complete the lighting function. Moreover, a complex PCBA can integrate many functions, such as the computer's motherboard PCBA, which integrates many components such as CPU sockets, memory sockets, and various interfaces, realizing a variety of data processing and input and output functions of the computer.

The production process is different

The production of PWB mainly involves the production of lines. It includes the transfer of the inner circuit pattern, etching, the inner layer blackening and other processes, and the focus is on creating an accurate conductive circuit pattern. For example, photolithography is used to transfer the designed circuit pattern to the copper clad laminate, and then remove the unwanted copper foil through etching to form the line.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.