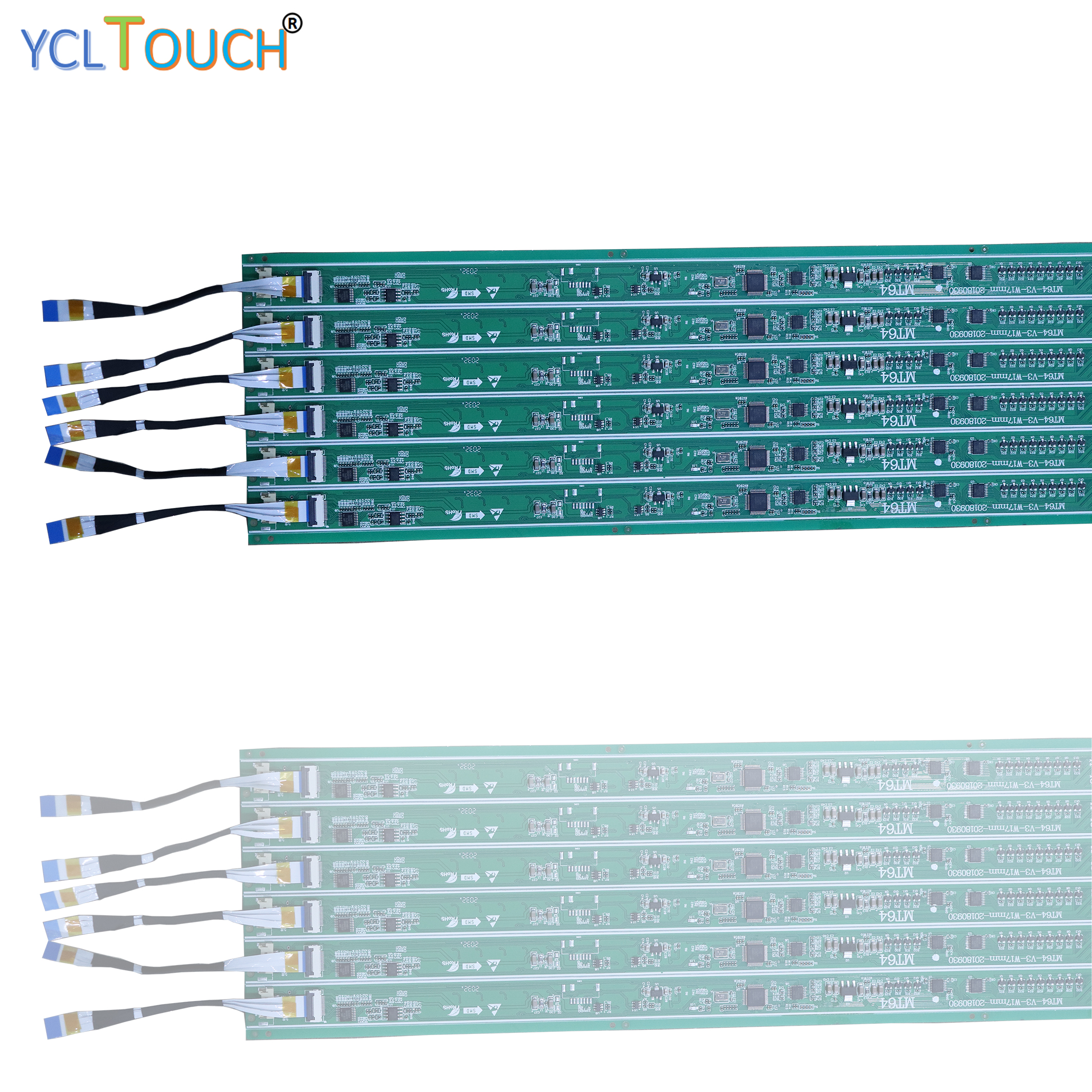

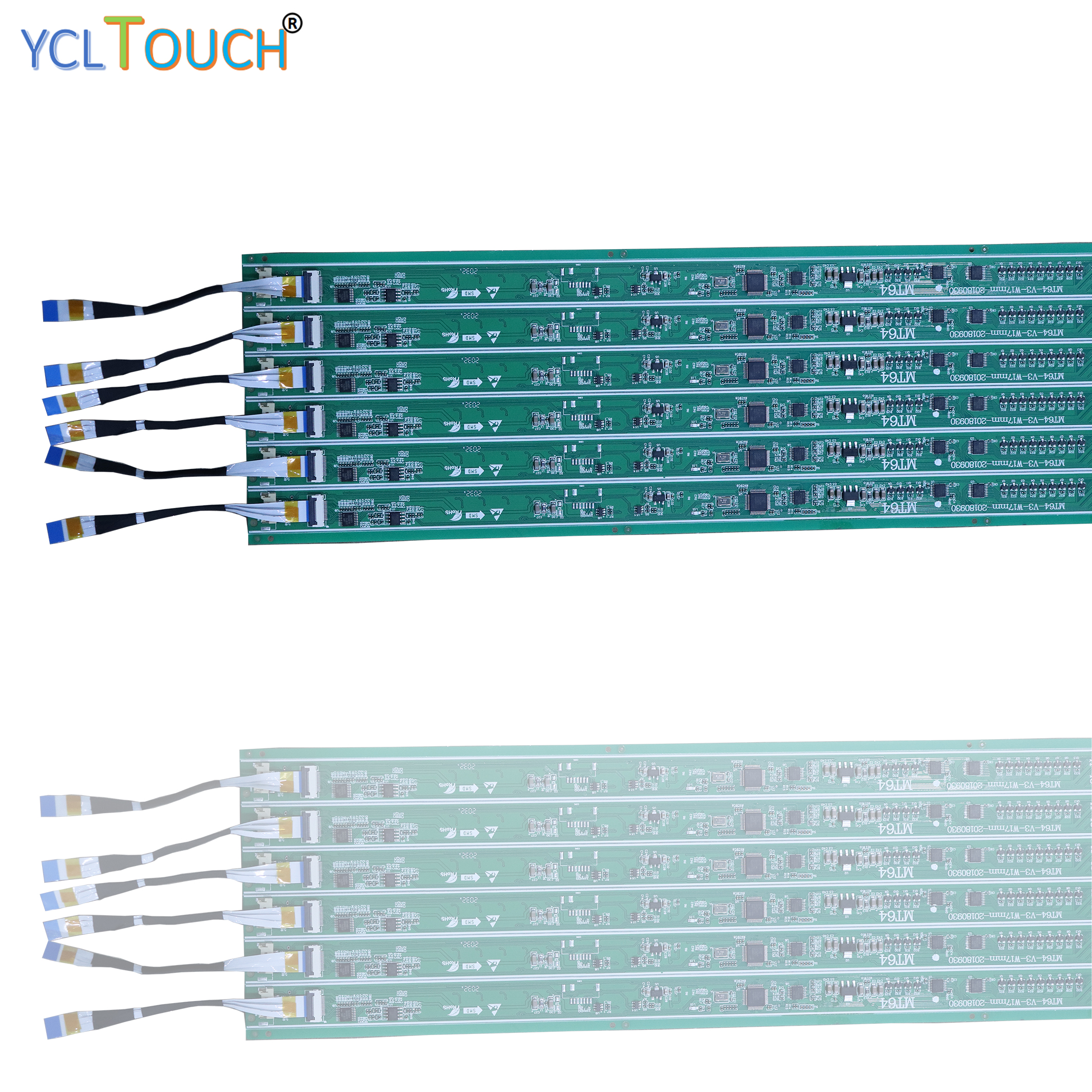

Infrared PCBA is Printed circuit board components, which is key concept in the modern electronics industry.In the manufacturing process,the first is PCB design and production.PCB is the basis of the bearing circuit, and its circuit layout is carefully planned according to the circuit principle, taking into account signal transmission, power distribution and other factors.

The next is procurement of components.According to the design requirements, select appropriate specifications, types of chips, resistors, capacitors, inductors and other electronic components, the quality of these components directly affect the performance of PCB. In the assembly process,for SMT,the tiny components are accurately mounted to the specified position of the PCB through high-precision mounter, which has fast mounting speed and high accuracy, and can meet the needs of large-scale production.

And then is the soldering process, which uses techniques such as reflow soldering (for SMT components) and wave soldering (for plug-in components) to form a firm electrical connection between the components and the PCB.From a functional point of view, PCB is a core part of electronic products. In consumer electronic products, such as the PCBA of smart phones, processors, memory chips, and communication modules are integrated to realize a series of complex functions from information processing and storage to wireless communication.In the Industrial control field,PCBA control key operations such as motor operation, sensor data acquisition and processing.

In the medical area, PCBA ensure high precision measurement and stable operation.For example:In the ECG machine,it is used for electrical signal processing.Quality testing is the key to PCBA, including appearance, electrical performance and functional testing, and strict testing to ensure its reliability and product quality.

Mr. zptouch01

Mr. zptouch01