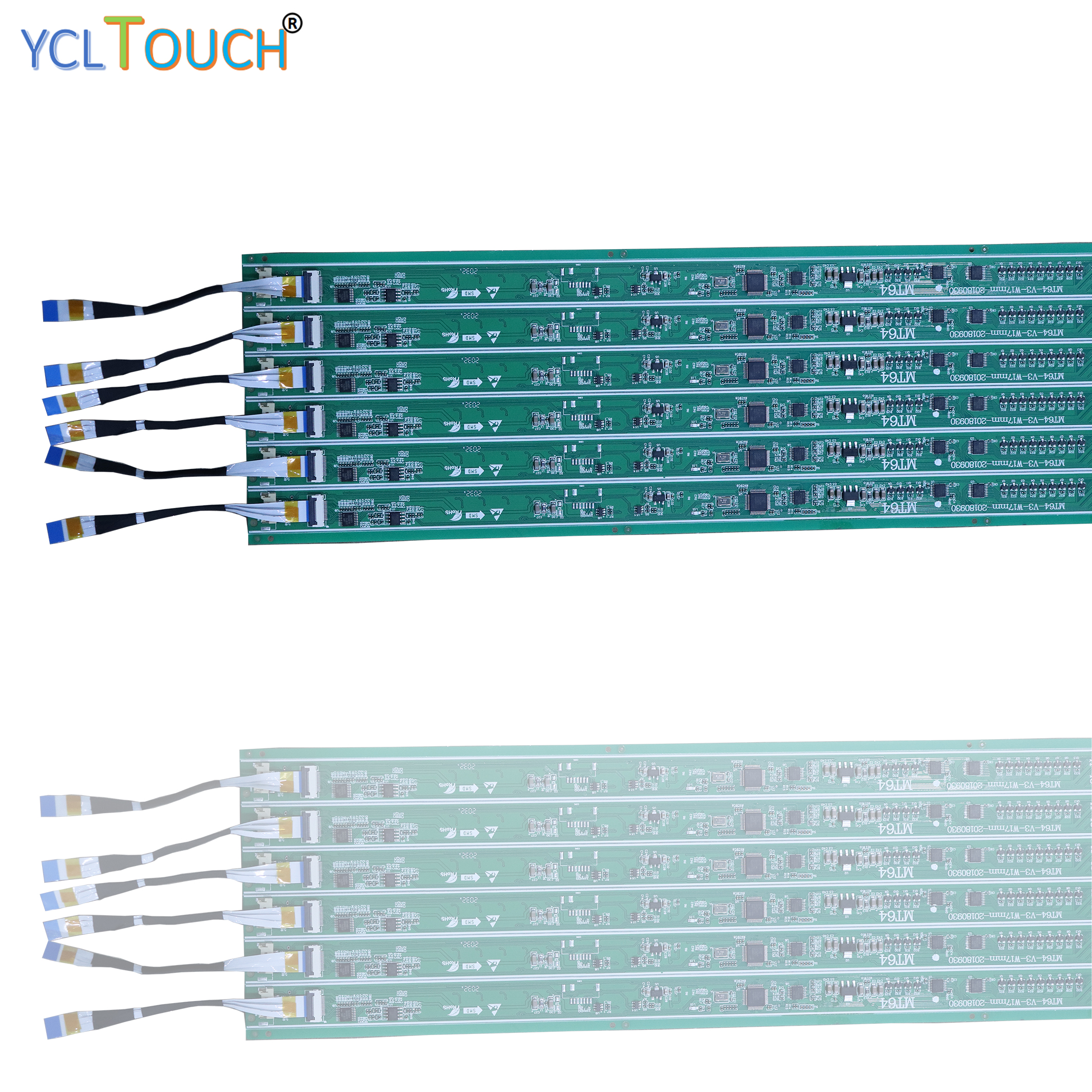

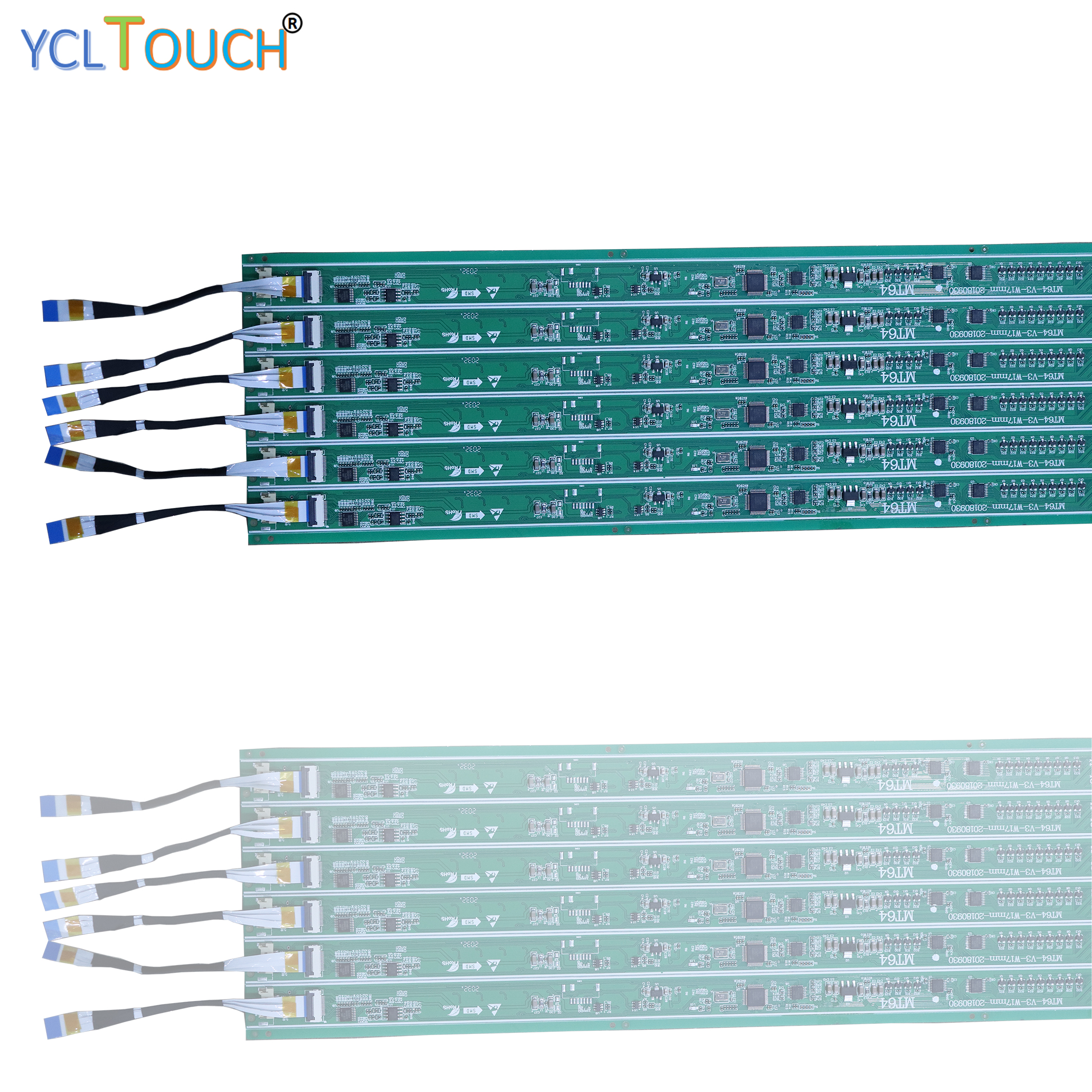

Definition of Infrared PCBA controller

- PCB (Printed Circuit Board Assembly) is a printed circuit board assembly. A PCBA controller is a control unit built on the basis of a printed circuit board assembly. It mainly implements specific control functions through the layout and connection of various electronic components (such as chips, capacitors, resistors, etc.) in the circuit. For example, in automation equipment, the PCBA controller can control the speed and direction of the motor, or monitor the data of the sensor, and accurately control the operation of the entire equipment according to preset programs and algorithms.

The composition of the PCBA controller

- Chip (microcontroller or microprocessor):This is the core part of the PCBA controller, and it's like the human brain. Pre-written program instructions are stored inside the chip, which are executed to control and process data for external devices. For example, a PCBA controller chip in a smart home system can control the switching and temperature regulation of an air conditioner based on the received temperature sensor data.

- Power Circuit:Provide a stable power supply for the entire PCBA controller. Power circuits are capable of converting external input voltages, such as mains or battery voltages, into the operating voltages required by chips and other electronic components. For example, convert 220V AC to 5V DC to ensure that the controller's internal components are working properly.

- Input/output interfaces:It is used to connect external devices such as sensors, actuators, etc. The input interface is responsible for receiving signals from external devices, such as information on the strength of the optical signal from a photoelectric sensor; The output interface is used to send control signals to external devices, such as closing or disconnecting signals to relays, so as to control the on/off of external circuits.

Functions of the PCBA controller

- Logic control function:Complex logical operations and judgments can be realized. For example, in an industrial automation production line, the PCBA controller can determine the next operation according to different product models and production processes, whether to start a certain motor for material transfer or control the robotic arm for product assembly.

- Data processing functions:Data collected from various sensors is processed. For example, in the environmental monitoring system, the PCBA controller can analyze the data from the temperature and humidity sensor and the air quality sensor, convert the original data into meaningful information, such as calculating the air quality index, and triggering alarms according to the set threshold.

- Communication Functions:Many PCBA controllers have a communication interface that enables data communication with other devices. For example, through wireless communication protocols such as Wi-Fi, Bluetooth, and Zigbee, or wired communication protocols such as RS-232 and RS-485, its own data can be sent to the host computer (such as servers or monitoring terminals), and it can also receive control instructions sent by the host computer.

Mr. zptouch01

Mr. zptouch01