1,Definitions and Differences:

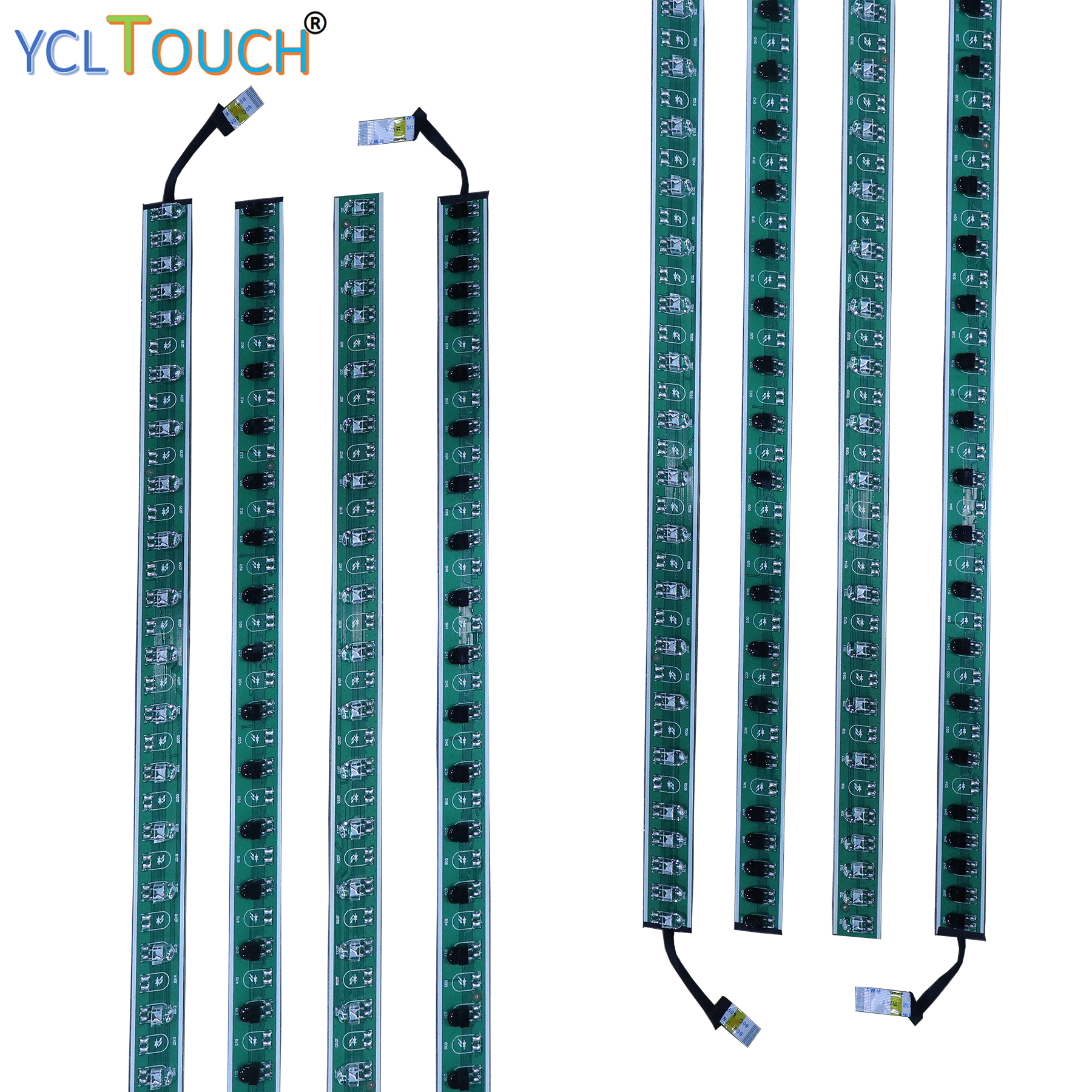

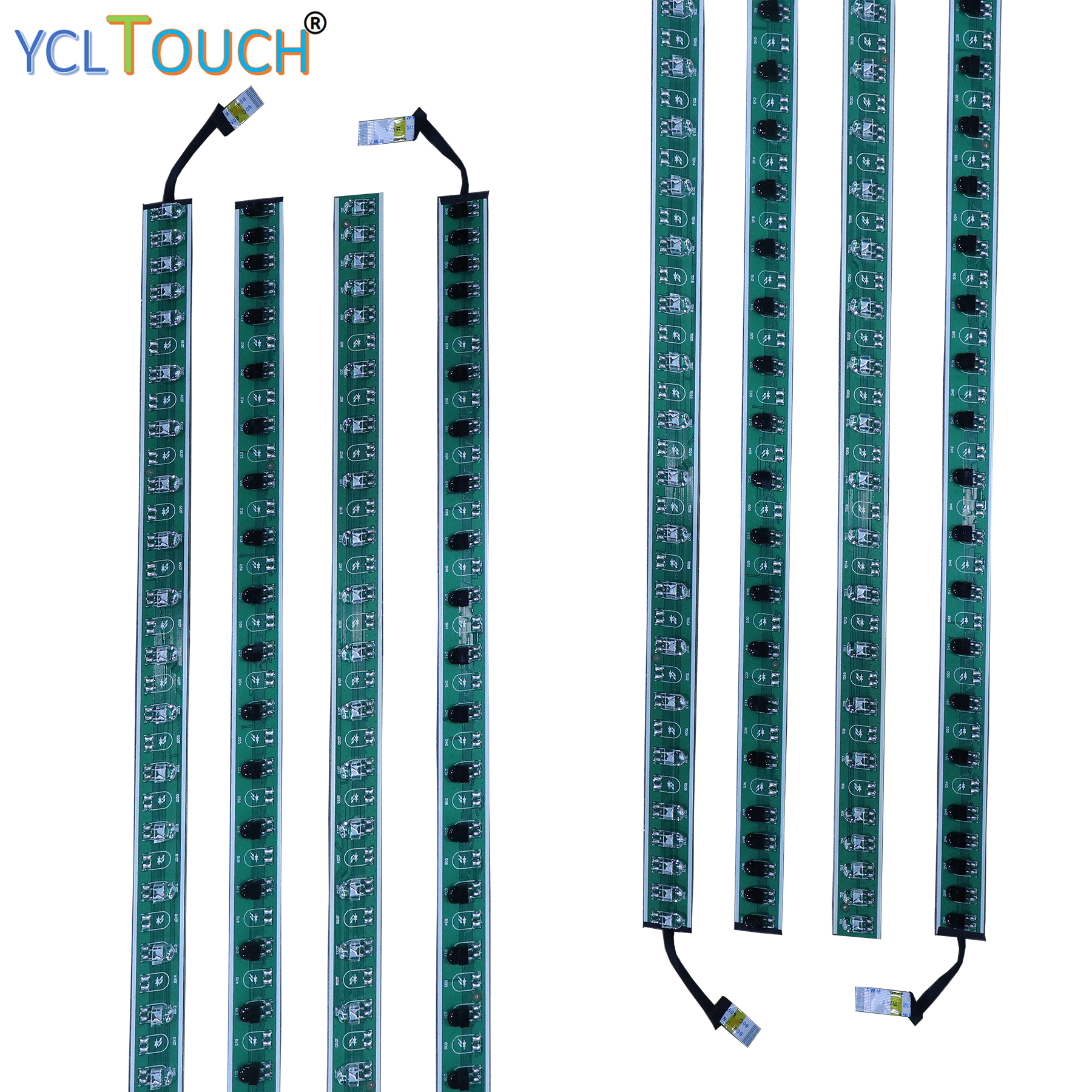

- PCB:A printed circuit board is a board with no electronic components. It is mainly composed of substrate, copper foil circuit and pad. The circuit is formed on the substrate through chemical etching and other processes, like a blank stage, only the basic frame and connection channels are set up, providing a place for the subsequent electronic components to "perform".

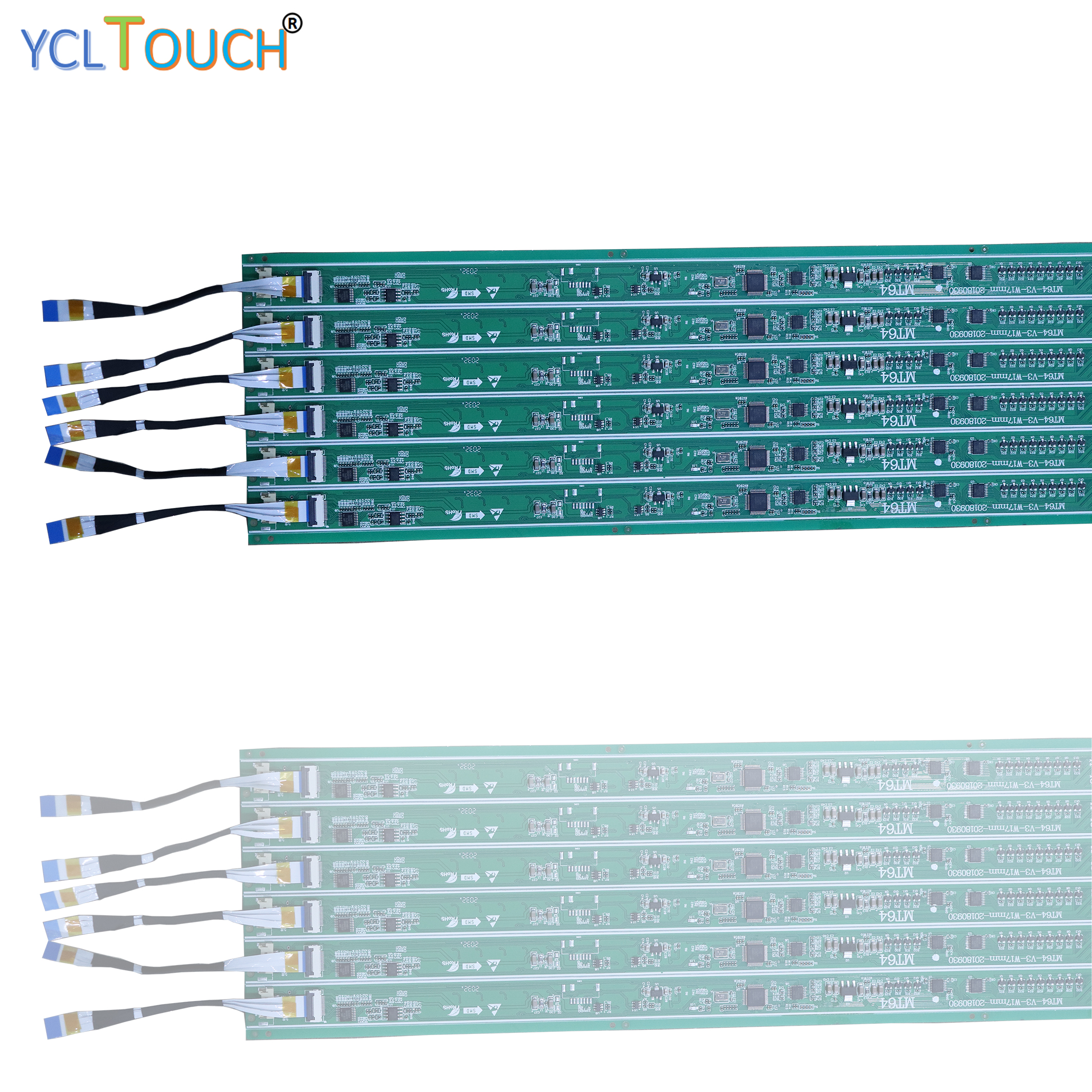

- Infrared PCBA:Printed circuit board assembly is the finished product after installing various electronic components (such as chips, capacitors, resistors, etc.) on the basis of PCB, and after a series of processes such as welding and debugging. It is equivalent to arranging actors (electronic components) on the stage, and rehearsing (debugging), and can directly "perform" (realize the function of electronic products).

2,Manufacturing process differences

- PCB:The first is design, where engineers use specialized software to plan the direction of lines and the placement of components. Then is the production process, including the production of the inner circuit, such as the use of lithography, etching technology to make the inner circuit on the copper clad plate; Then the lamination (for multi-layer board), the inner circuit and insulation layer laminated; After that, the outer circuit production and surface treatment, such as tin plating, gold plating to enhance the pad performance.

- PCBA:First components procurement, select the components that meet the requirements. Then surface mount technology (SMT) or plug-in (DIP) mode is used to mount the components onto the PCB. SMT is to mount tiny components accurately through automation equipment, and DIP is mainly used for pin insertion of larger components. After that, soldering is performed, the SMT elements are reflow soldered, and the DIP elements are wave soldered or manually soldered. Finally, the inspection is carried out, including appearance inspection and electrical performance test.

3,Application Scenarios:

- PCB:In the early stage of electronic product design, it is used to verify the feasibility of circuit design and determine whether the circuit layout is reasonable. At the same time, in some simple electronic production activities or educational scenarios, as a basic circuit board for users to install components and experience the electronic production process.

- PCBA:It is widely used in various mature electronic products, such as smart phones, tablet computers, industrial control equipment, etc. These products require that the circuit board can work normally directly after the installation of components, PCBA just meets this demand, it is the key component of electronic products to realize the function.

Mr. zptouch01

Mr. zptouch01